Feedstocks to Fuel: Testing to Ensure a Resilient SAF Supply

Liam Mills

Sustainable Hydrocarbon Specialist

Intertek Caleb Brett

Feedstocks to Fuel: Testing to Ensure a Resilient SAF Supply

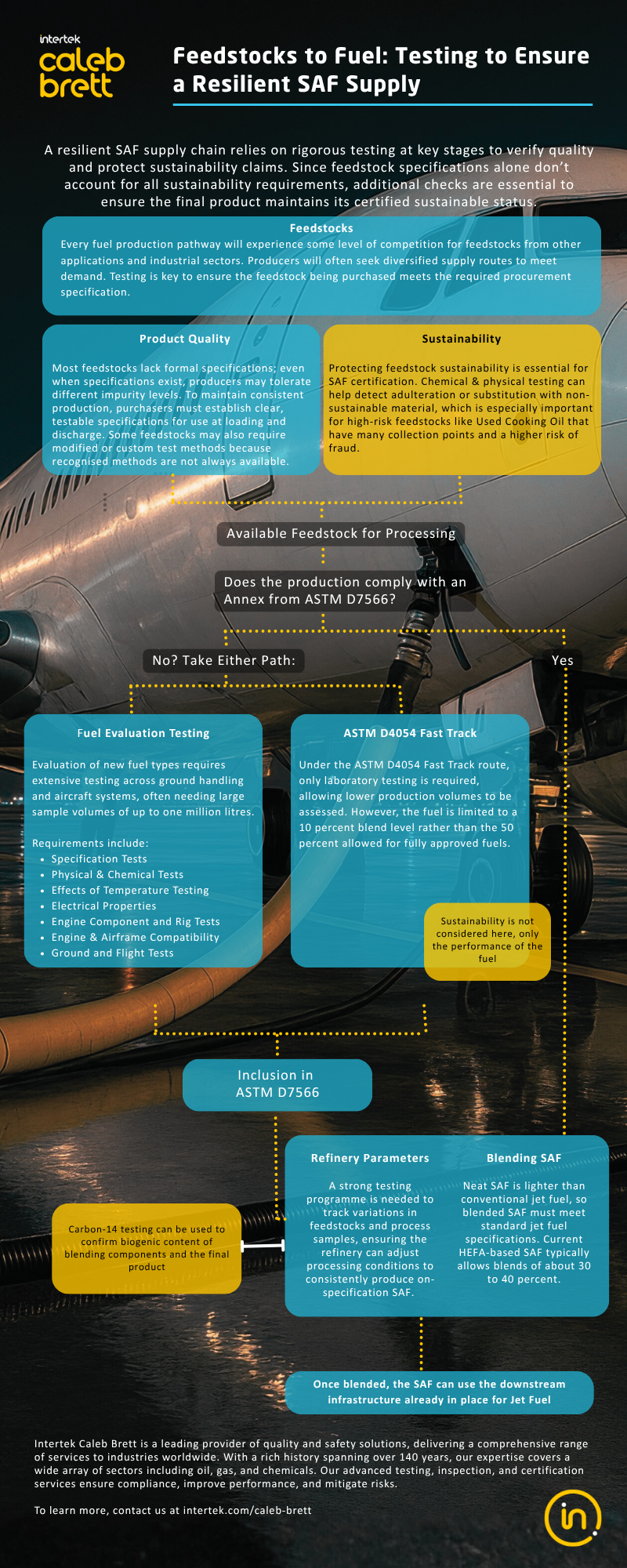

As the aviation sector increases its commitment to net zero targets, Sustainable Aviation Fuel (SAF) continues to take centre stage. Industry leaders agree that scaling SAF production is essential, but many overlook the quieter force that determines whether SAF is truly reliable: testing.

From the moment a feedstock is collected to the moment blended fuel enters an aircraft, testing is the thread that holds the entire supply chain together. Without consistent, verifiable data, producers risk off specification batches, purchasers risk inconsistent performance, and certification bodies risk invalid sustainability claims.

For an industry moving at a rapid pace, confidence in product quality and sustainability is no longer optional. It is the basis of a resilient global SAF market.

Feedstocks: Where Resilience Begins

The most impressive SAF pathway cannot deliver on quality or yield if the feedstock is inconsistent. Every pathway competes with other industries for materials. HEFA producers compete for UCO, tallow, and other lipids. ATJ producers compete with beverage, chemical, and bioenergy markets for ethanol and methanol. Power to Liquid pathways depend on carbon sources that are now in demand across multiple sectors.

With competition rising and global availability tightening, feedstock quality cannot be assumed. It must be proven.

Most SAF feedstocks do not have standardised global specifications. Even where specifications exist, producers may tolerate different impurity levels based on their process design. This creates an uneven playing field that can only be managed through testing.

Industry purchasers should establish clear, testable specifications and apply them at every transfer point. Variability introduced at loading or discharge can disrupt production, affect yields, or make certification impossible.

Emerging feedstocks bring additional challenges. Some require modified or novel test methods to detect critical contaminants or trace components. Producers and purchasers who invest in strong analytical partnerships are better positioned to protect supply integrity.

Product Quality: Monitoring What Matters Most

Once a feedstock reaches the refinery, rigorous process testing becomes essential. SAF production is sensitive to changes in feedstock composition. Operators need frequent data on acidity, sulfur content, oxygenates, trace metals, and other variables that can shift without warning.

For producers operating under an approved ASTM D7566 annex, tight process control protects both quality and yield. It also prevents the costly outcome of producing off-specification SAF.

For producers developing new pathways that are not yet approved under ASTM D7566, the testing requirements increase dramatically. New fuels must demonstrate safe performance across storage, handling, materials compatibility, engine operation, and aircraft systems. Up to one million litres of fuel may be required for evaluation. This includes specification tests, chemical and physical property assessments, thermal stress testing, electrical property analysis, rig testing, engine and airframe trials, and both ground and flight tests.

In these cases, performance testing takes priority. Sustainability is verified through separate frameworks. Without strong test data, new SAF technologies cannot progress toward market approval.

Sustainability: Protecting the Attribute That Makes SAF Valuable

As demand rises, so does scrutiny on sustainability claims. Feedstock fraud, adulteration, and substitution pose legitimate risks. If these issues go undetected, entire batches of SAF can become uncertifiable despite meeting technical performance requirements.

Verification is especially important for high-risk feedstocks such as Used Cooking Oil, which is collected through thousands of distributors and aggregators worldwide. Chemical fingerprinting, contaminant screening, and forensic analysis help identify inconsistencies that may indicate substitution with non-sustainable material.

Producers, traders, and purchasers who incorporate targeted sustainability testing gain stronger protection against traceability issues and certification failures. This is not only a regulatory expectation but also a competitive advantage.

Blending and Distribution: The Final Gatekeepers of Quality

After production, SAF must be blended with conventional jet fuel. Neat SAF often has lower density than fossil derived jet fuel, so blending must be carefully controlled to meet ASTM D1655 requirements.

HEFA blends commonly fall within the 30 to 40 percent range. As blending levels increase, testing becomes more important because properties such as freeze point, density, and aromatic content must remain stable.

Producers developing new fuels through the ASTM D4054 Fast Track route can enter the market earlier with blends of up to 10 percent by volume. While these fuels do not yet achieve the higher blending limits of fully approved pathways, they bring valuable diversification to the market. Strong testing helps these fuels move smoothly through existing jet fuel infrastructure without disrupting downstream operations.

What Industry Experts Should Take Away

The path to a resilient SAF supply is not built on production volume alone. It is built on measurable, verifiable data that protects every stage of the supply chain. Purchasers gain security in quality. Producers protect yield and compliance. Airlines gain confidence in performance. Regulators gain confidence in certification.

Testing is the factor that enables scale, trust, and long-term stability.

About Intertek Caleb Brett

Intertek Caleb Brett supports the global energy and fuels industry with independent testing, inspection, certification, and advisory services. With more than 130 years of technical experience, the business delivers comprehensive analytical testing for SAF feedstocks, intermediates, and finished fuels. Services include verification of feedstock authenticity, process control testing for production facilities, and full specification analysis for blended and unblended SAF. Through a global network of laboratories and expert teams, Intertek Caleb Brett helps organisations strengthen supply chain resilience, achieve product consistency, and meet international standards with confidence.

About Liam Mills, Intertek Caleb Brett, Sustainable Hydrocarbon Specialist

Liam Mills holds a degree in Chemistry with Forensic Analysis from Loughborough University and has been a key part of the Intertek team since 2008. With more than 15 years of experience in the Energy Industry, Liam is deeply involved in research and development of sustainable fuels, driving innovation and ensuring quality in emerging energy sectors. His expertise extends to participating in various technical committees, including the Energy Institute and ASTM, where he contributes to the development of industry standards and sustainable practices for hydrocarbons.